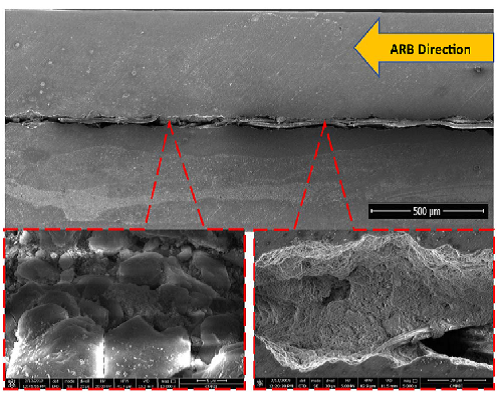

FE-SEM micrographs of Al/1wt%Al 2O 3 composites ARB direction section and representing the interface of Al2 O 3 cluster with Al matrix after one cycle

Accumulative roll bonding (ARB) technique is used in this paper to produce aluminum/alumina composite sheets. Alumina

content was added as 1,3 and 5wt%. The produced Al/Al2O 3 composite sheets are piled up and processed by accumulative

roll bonding (50% reduction) after preheating at 280 °C with different regimes (2–8 cycles). Statistical design analysis

was applied to examine the effects of alumina content and no. of accumulative roll bonding cycles on the ultimate

tensile strength for aluminum/alumina composite sheets. Empirical formulas were deduced to recognize key parameters that

controlling tensile behavior. XRD detection was carried out to explore dominant planes controlling plasticity Al/Al2O 3

composites. In general, addition of alumina and proceeding different cycles increases strength. FE-SEM microstructure

showed that alumina plays important roll on the aluminum sheets during ARB process where the metal of aluminum flow

among them producing highly sheared matrix.

Read More